JCB LiveLink

Fleet management through connected technologies

The challenge

Atomic were tasked with updating JCB’s existing Livelink fleet management platform with a more robust and advanced system. The upgraded system would be required to ingest large quantities of data from multiple sources and provide detailed metrics to support operators in managing machinery fleets more effectively and efficiently. A key challenge to overcome was the handling of multiple data-sets with multiple specifications, both in terms of the volume of data storage required and in developing a system that could read and report on the data in a meaningful way.

The solution

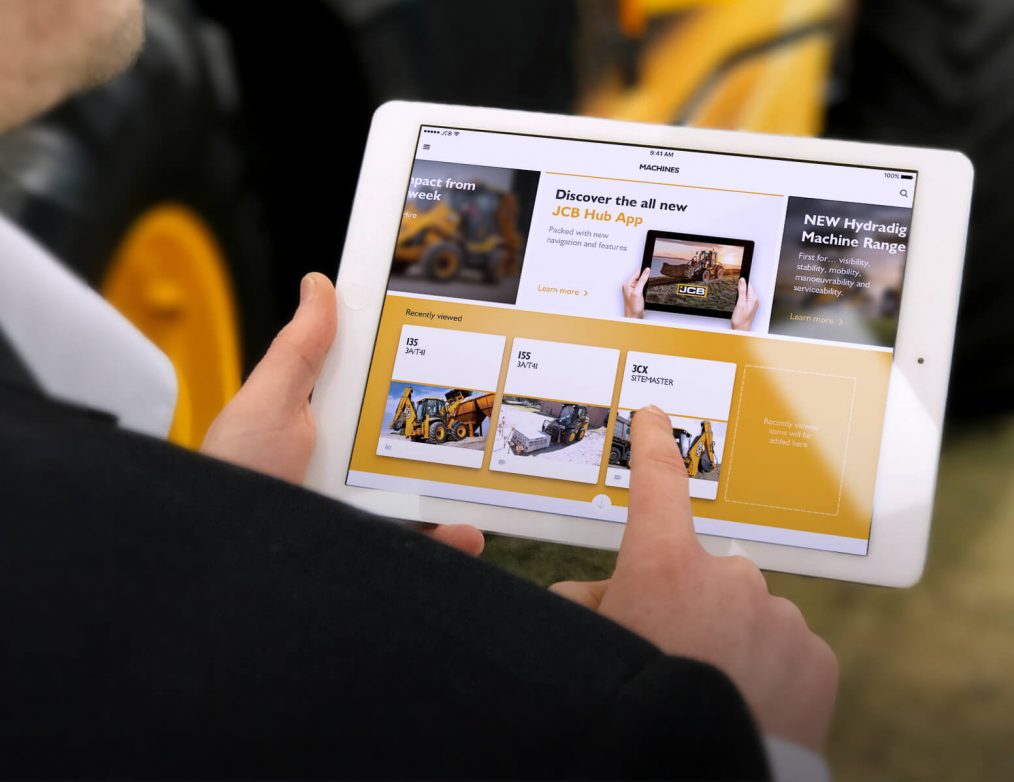

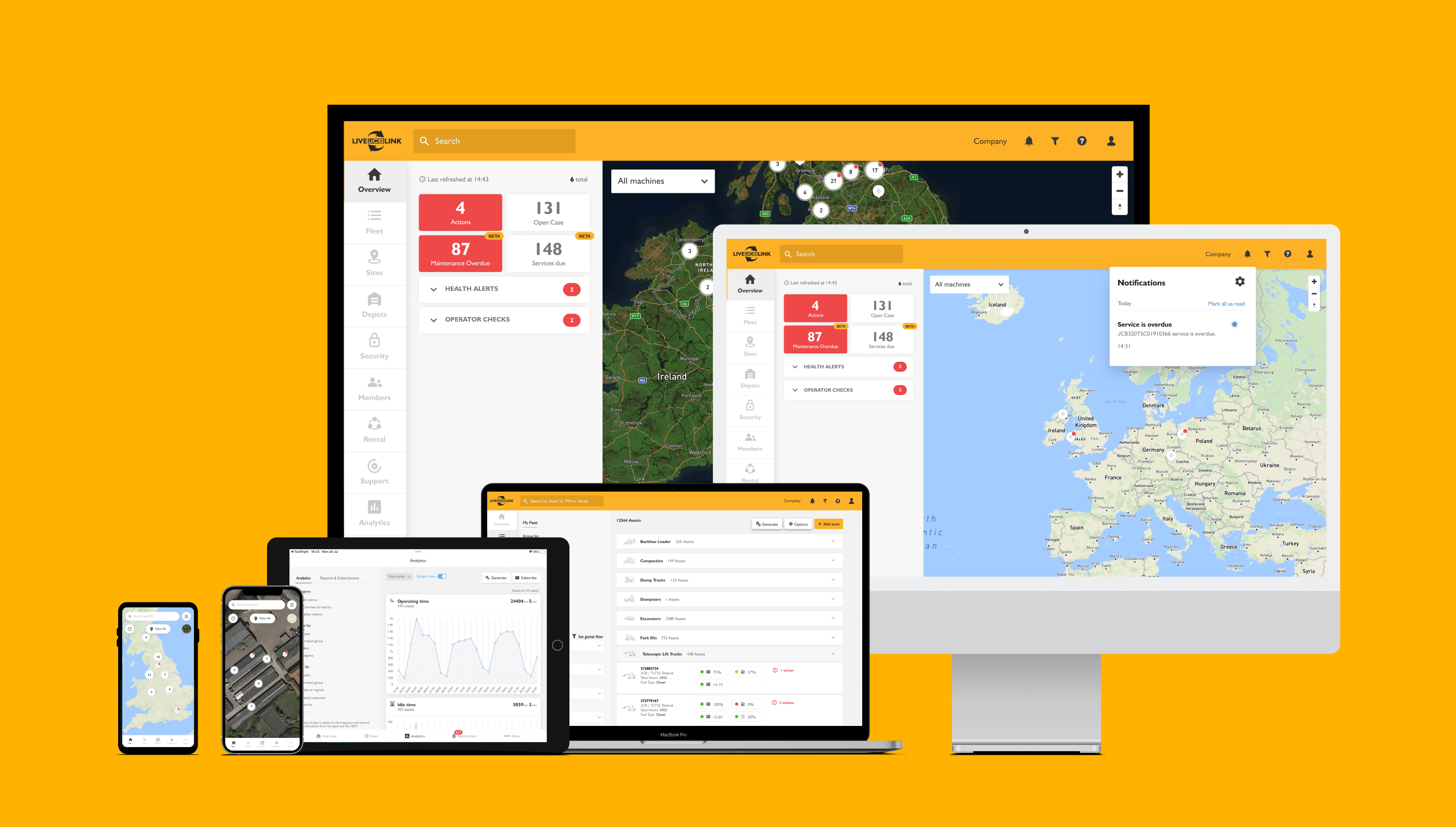

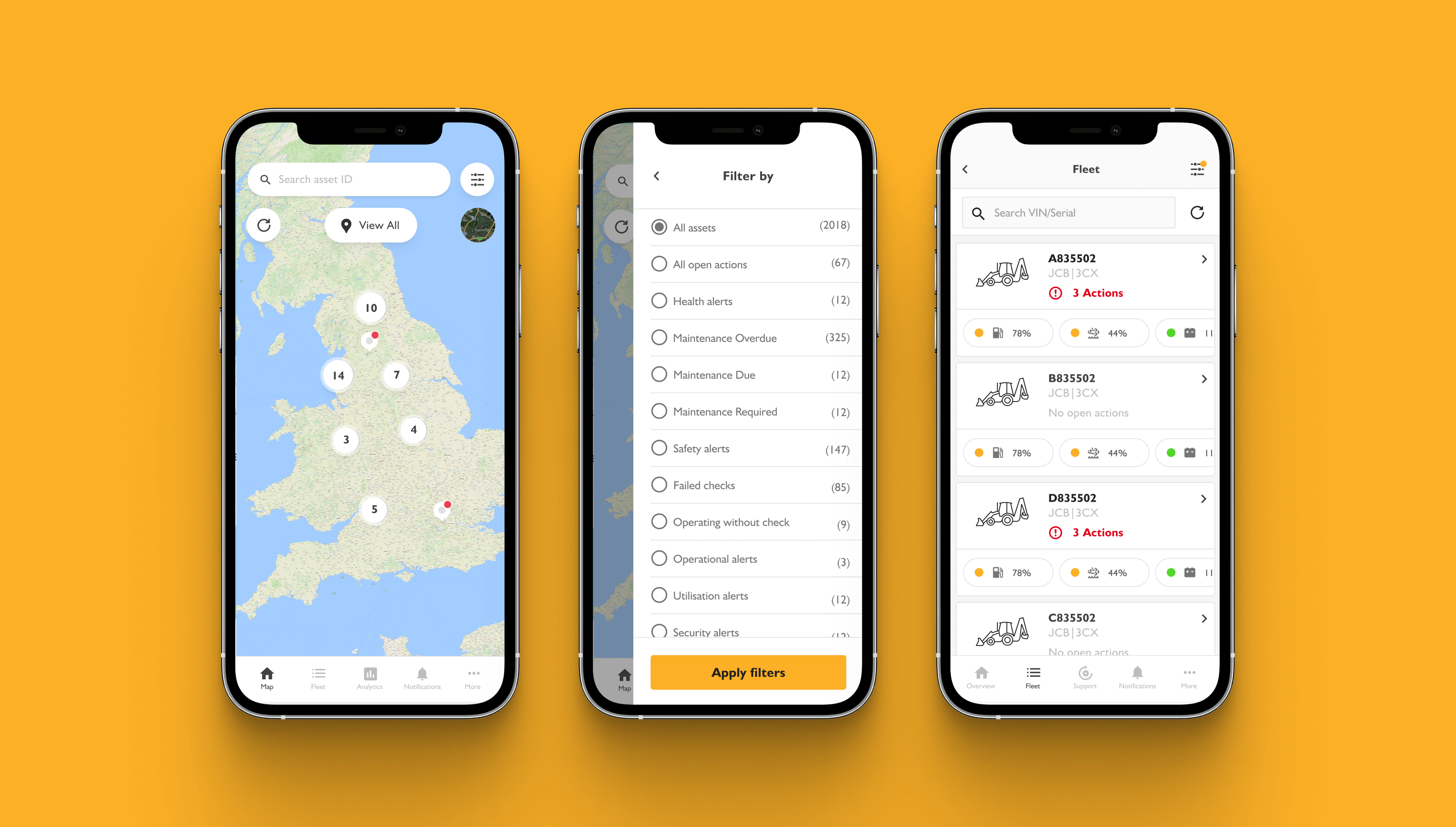

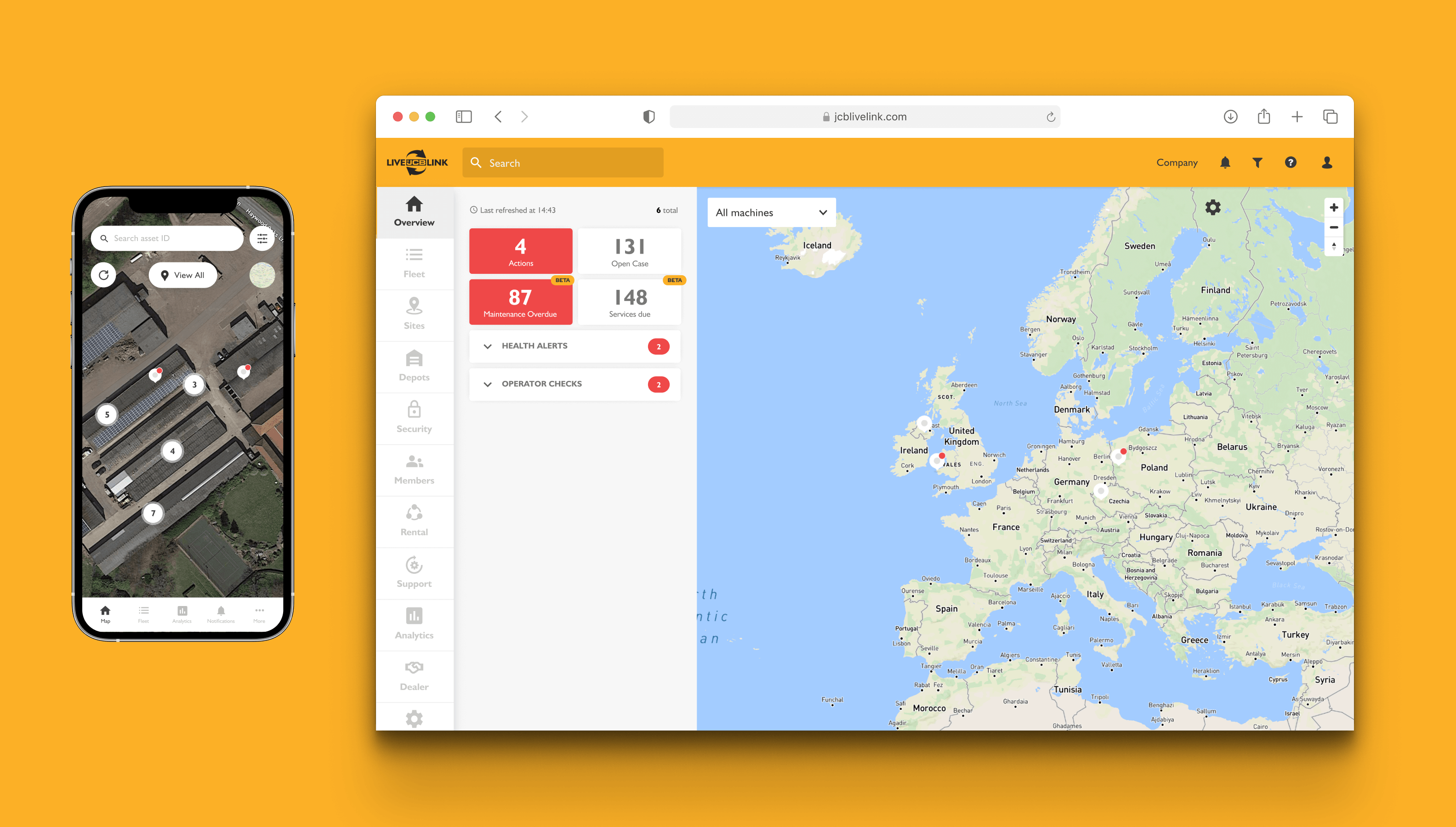

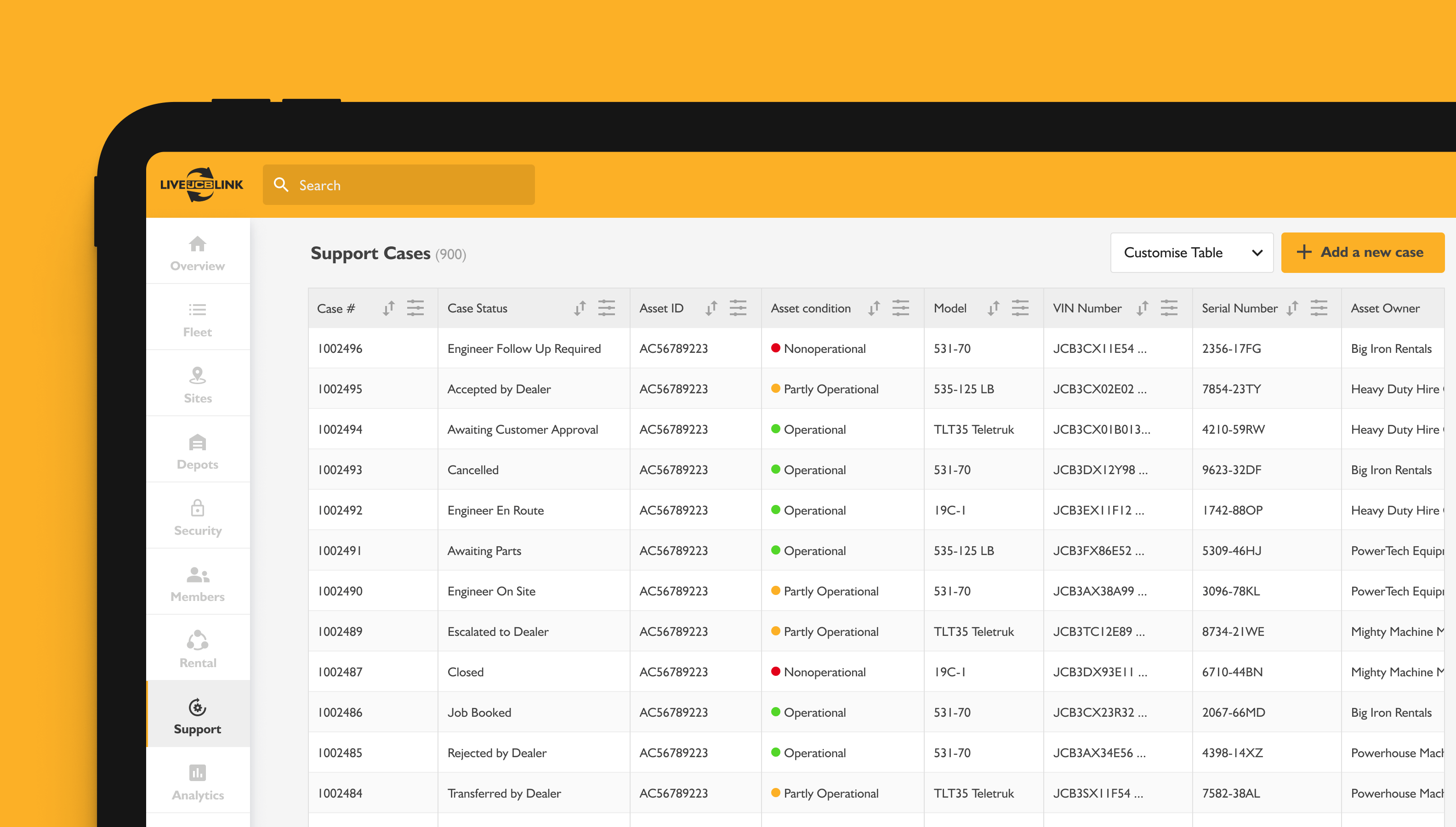

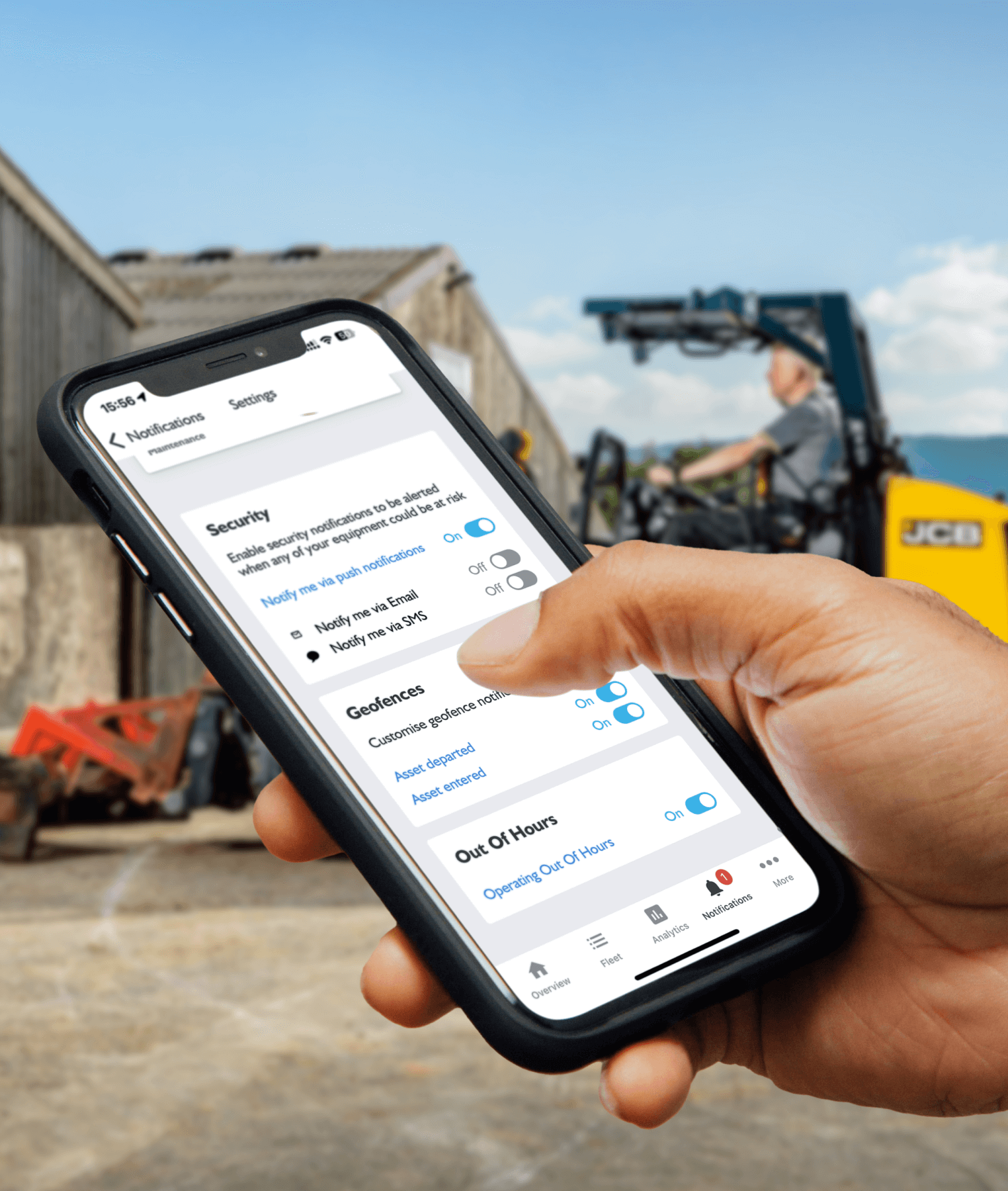

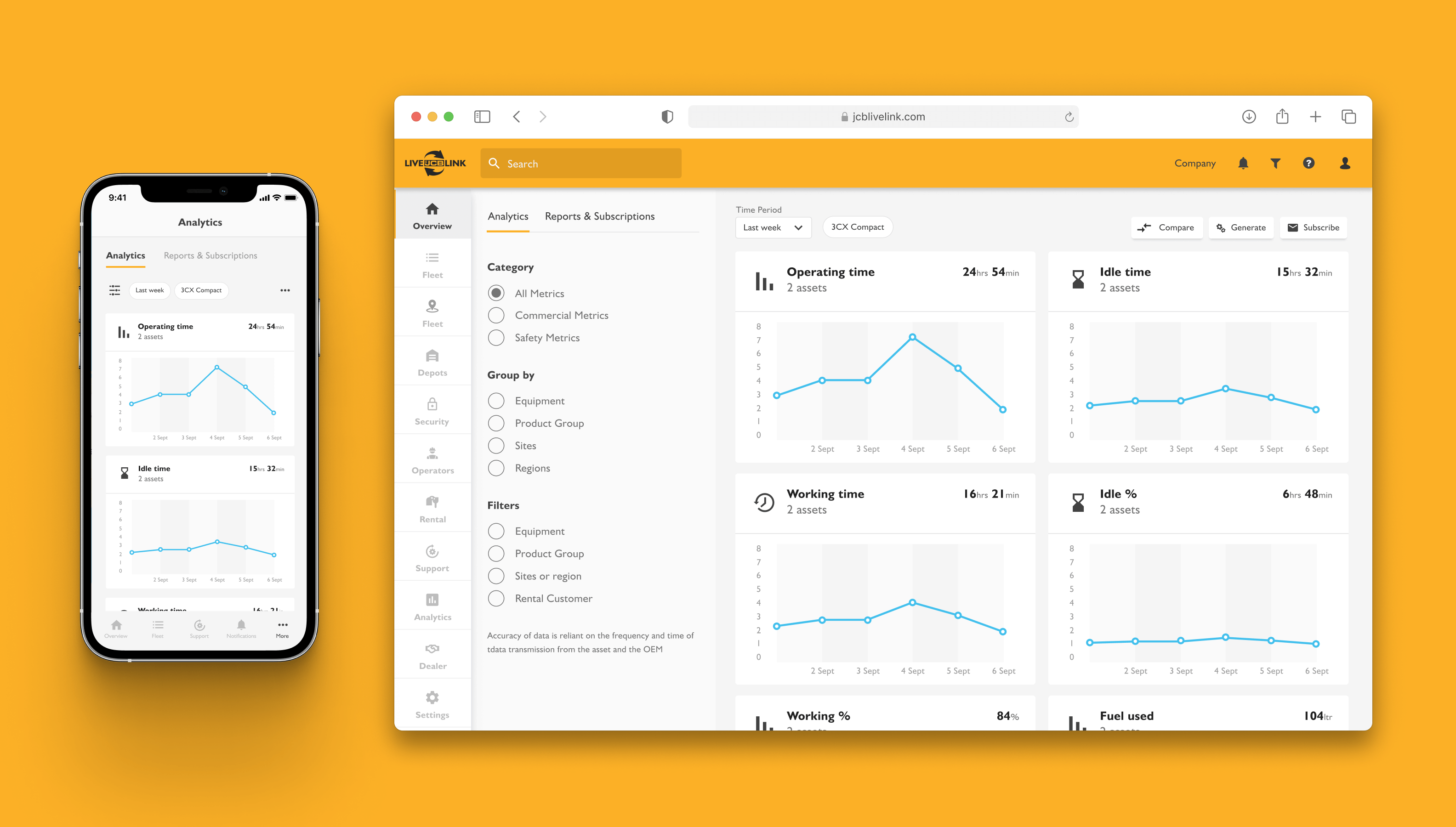

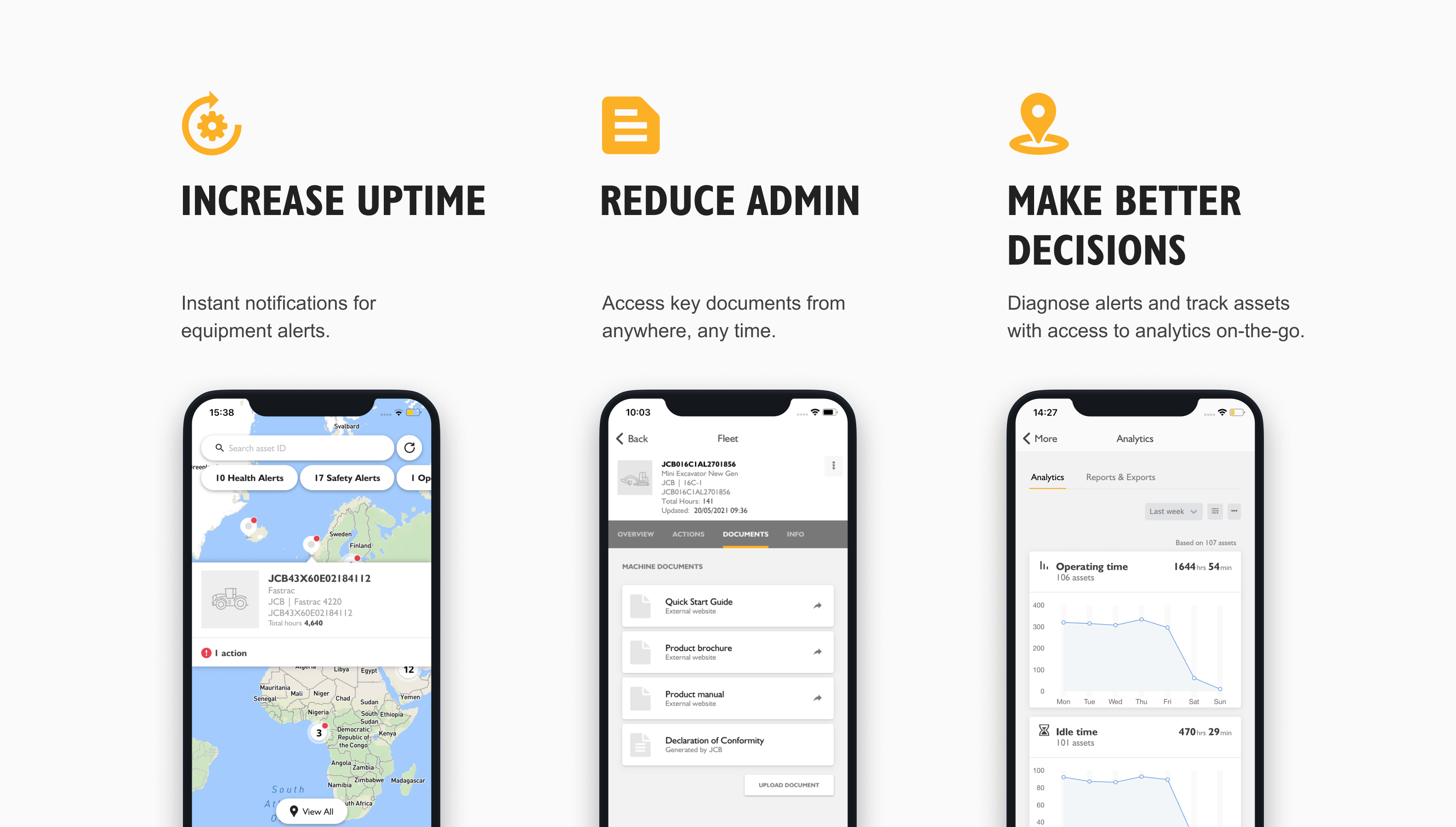

The upgraded Livelink system was developed as a web-based platform with iOS and Android versions also available. The system collects and ingests data transmitted by onboard machinery and interpolates the data, presenting it in easily digestible and customisable reports to the user, enabling them to manage their fleet more effectively.

The outcome

The new Livelink system developed for JCB allows for much more accurate and user-friendly reporting of fleet-management data. It has been adopted worldwide by JCB and its customers, ensuring JCB assets in the field are being used to their optimum and that projects utilising JCB equipment are running as efficiently as possible. For example, the platform is currently being used by Balfour Beatty on the HS2 project to report on metrics such as CO2 emissions. This will enable Balfour Beatty and, by extension the HS2 Project, to limit the environmental impact from emissions.

What our clients say

"We view Atomic as more than a supplier. They form an integral part of our team and what we do at JCB."

A universal approach to data specification

Machine-led algorithms were developed which can provide advanced interpolation of data received and intelligently infer missing data with a high degree of confidence. Simultaneously, legacy data was preserved to be recalled for analytics purposes.

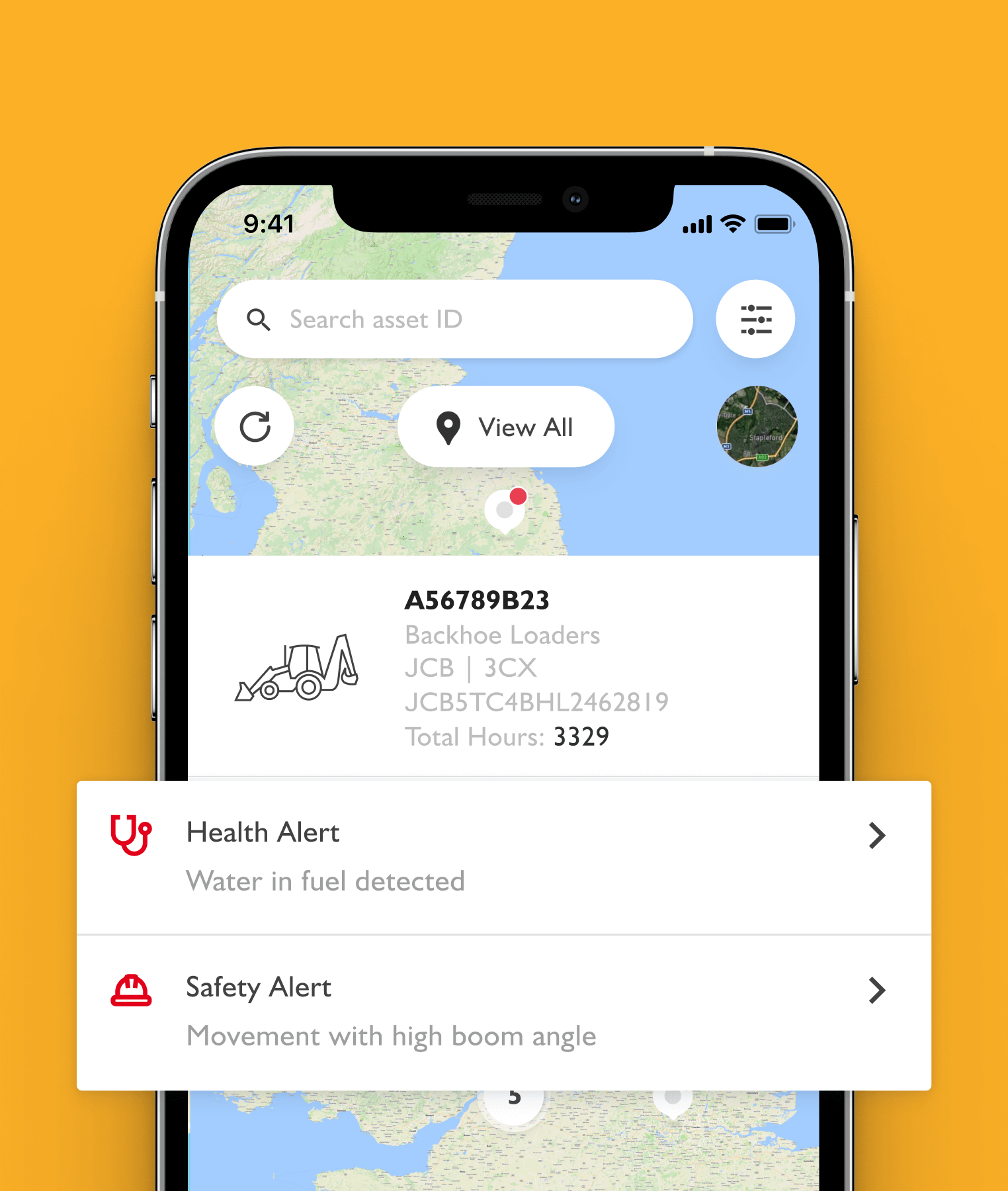

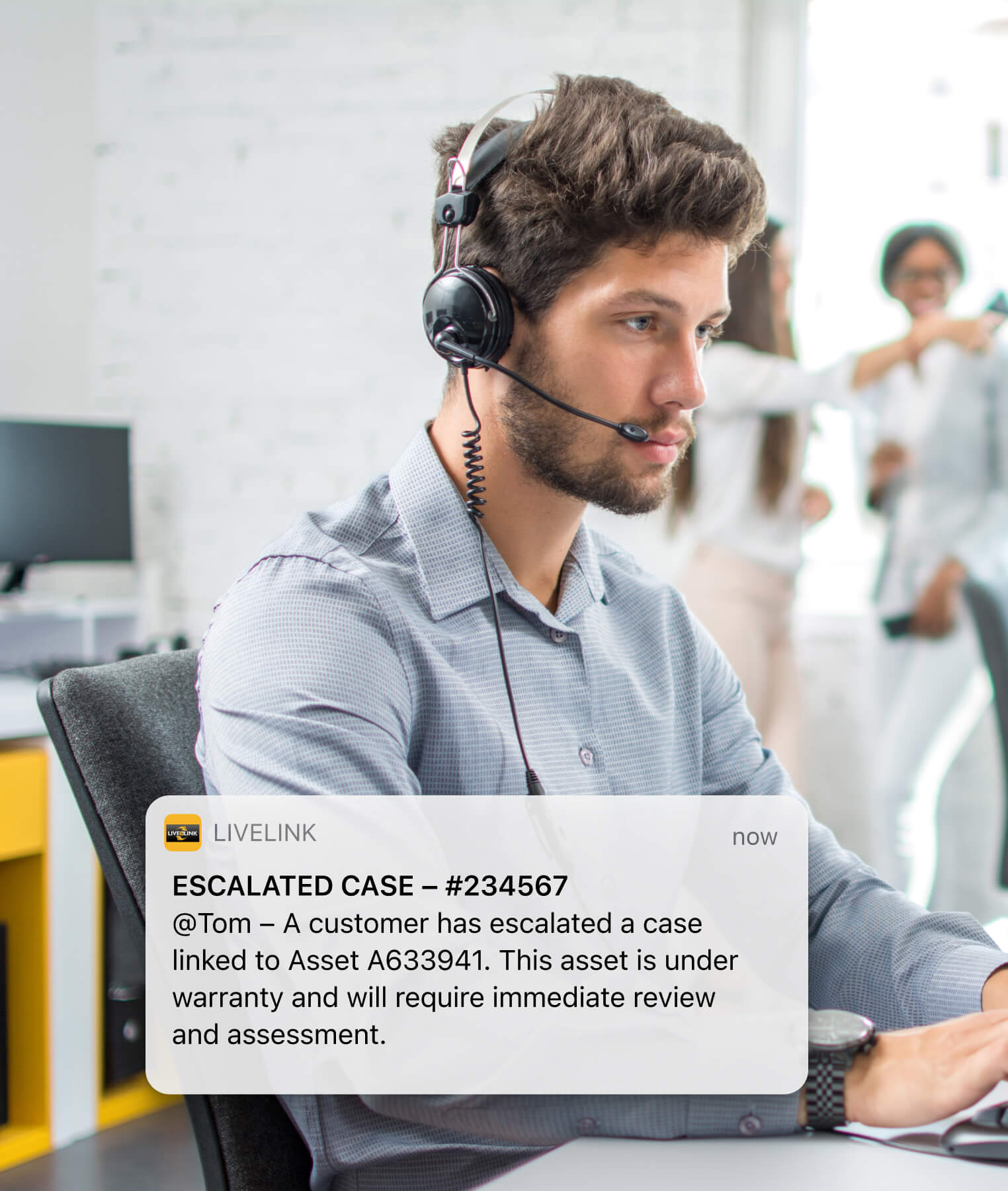

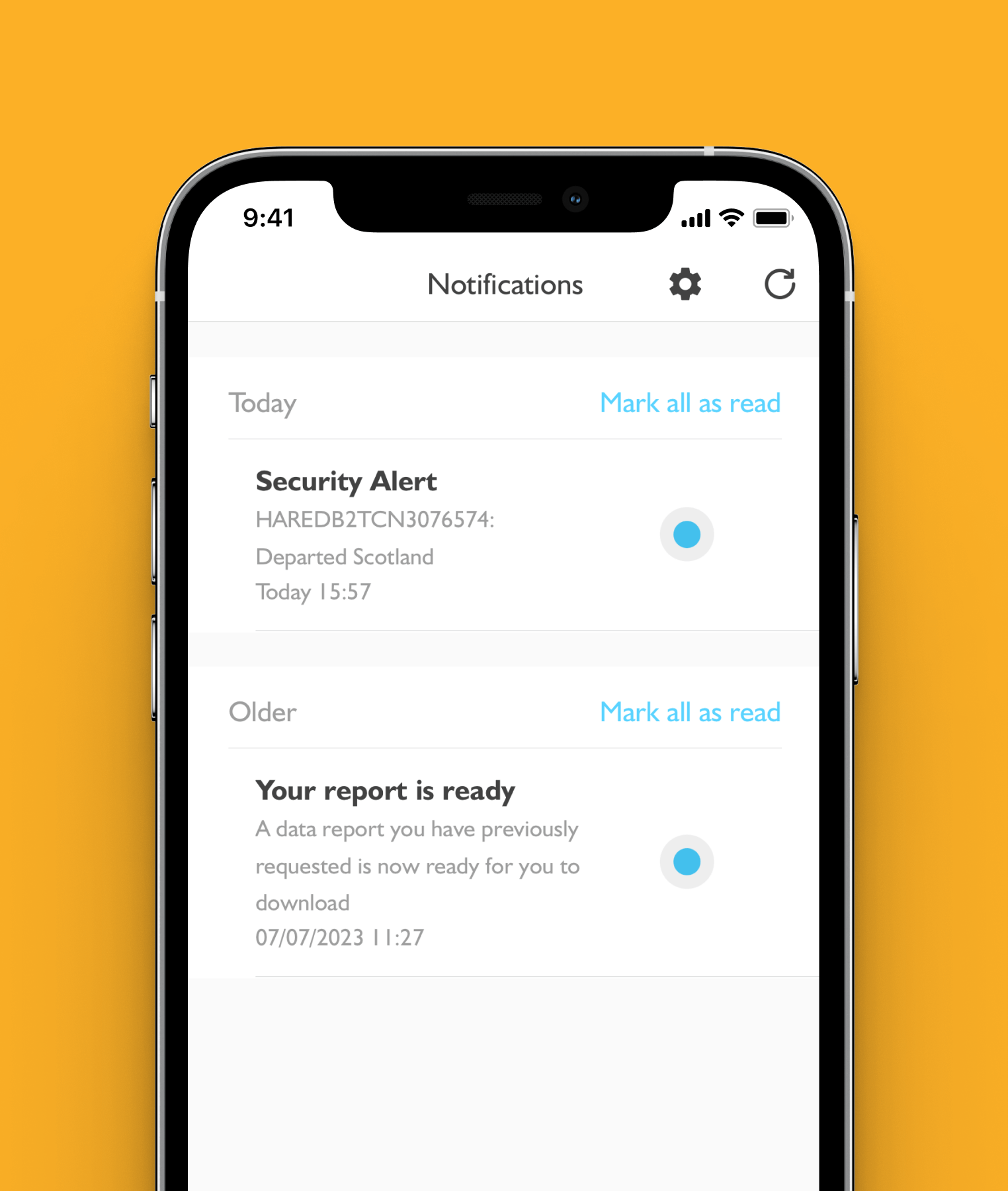

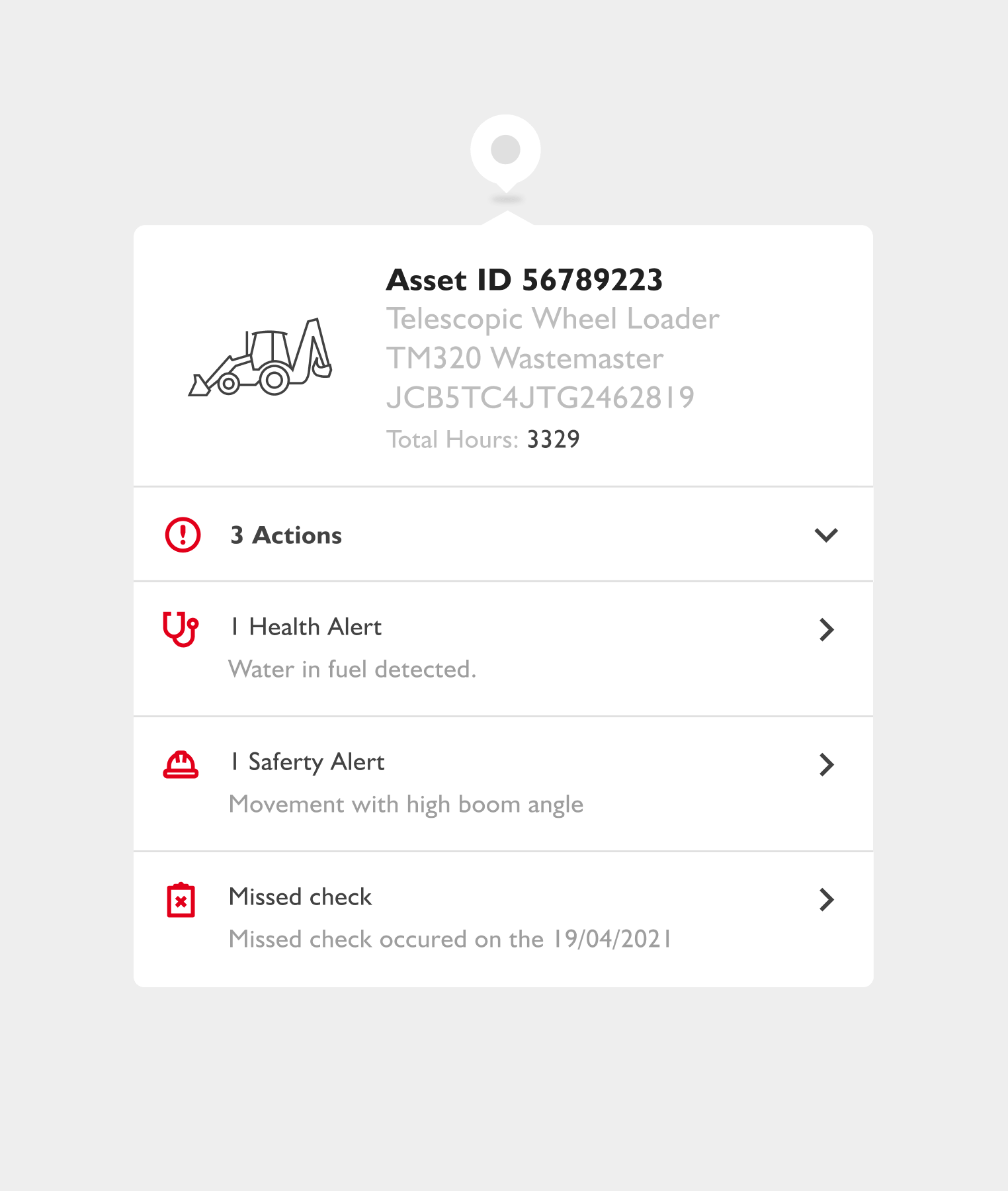

Advanced early warning system

The Atomic team developed a learning algorithm. This allowed the system to identify the conditions in which a fault is likely to occur and alert the user to a potential emerging fault. This allowed for preventative maintenance, eliminating costly machine downtime later on.

A more efficient fleet with downtime monitoring

The system tracks machinery downtime and allows the user to identify which machines they have in the field that are currently being unutilised. This allows for redeployment of idle machinery and better future planning.

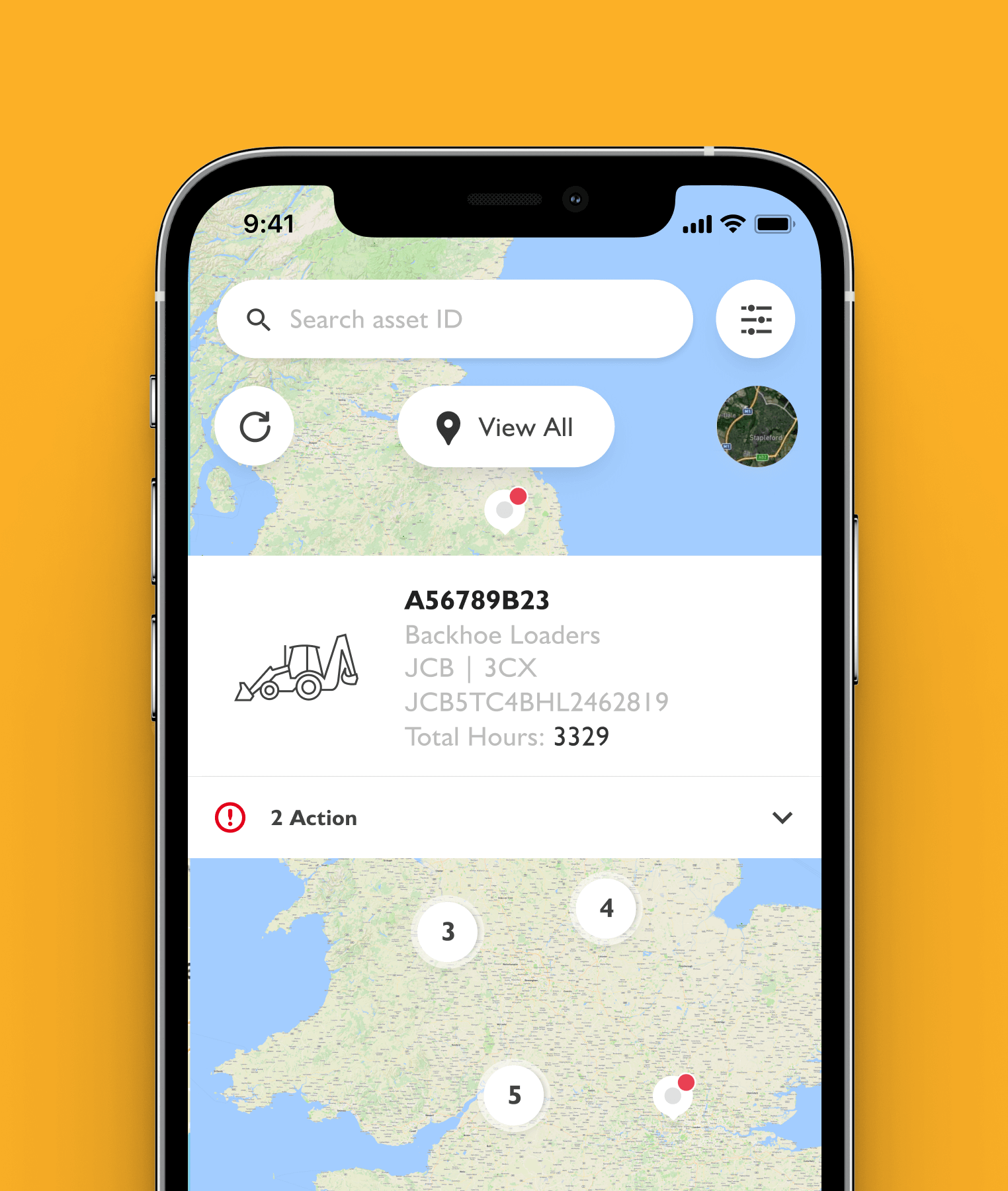

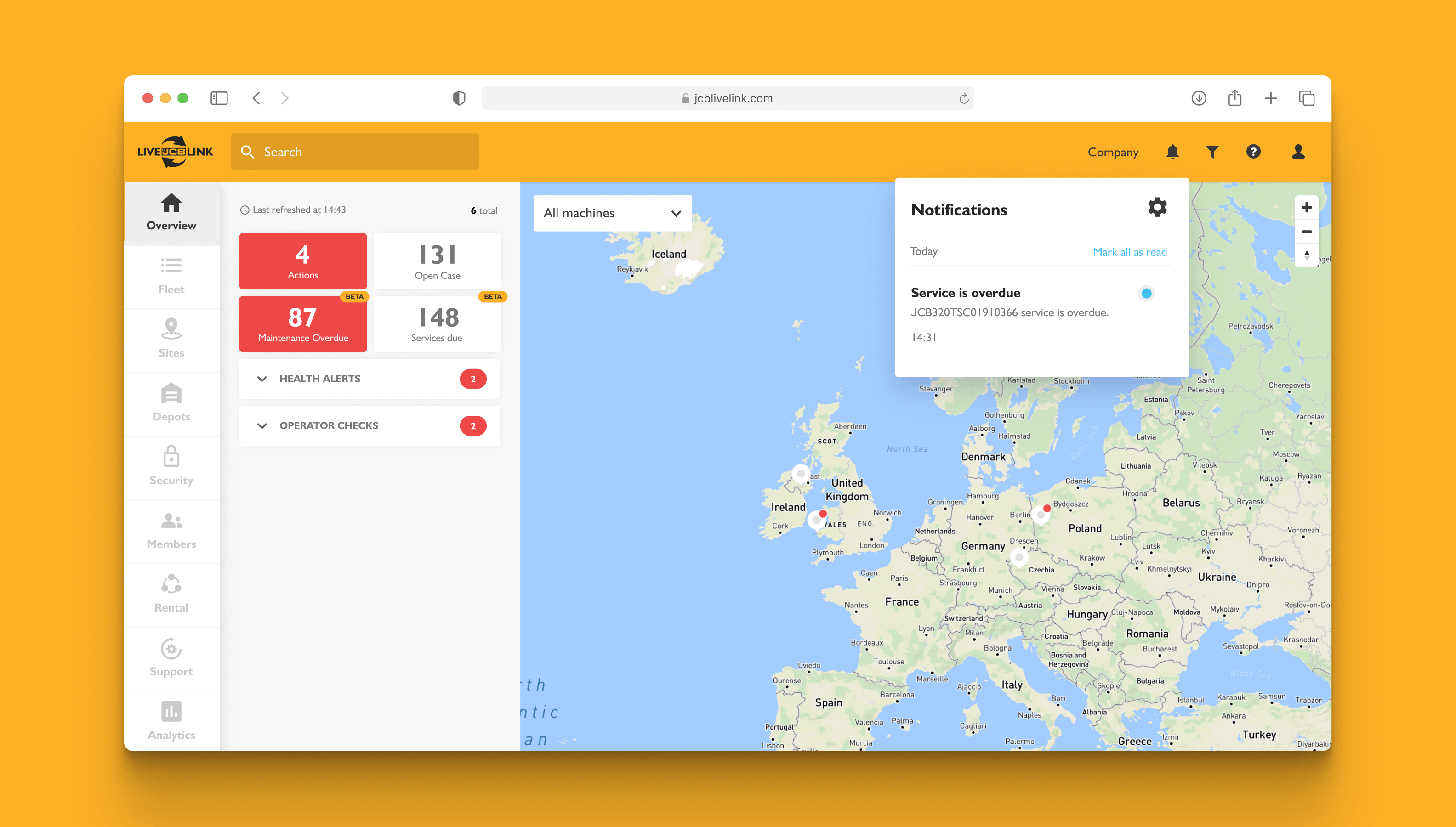

Keeping track of your fleet, anywhere in the world

The Livelink system shows each machine’s geographical location at any given time, as well as that machine’s current application and employment.

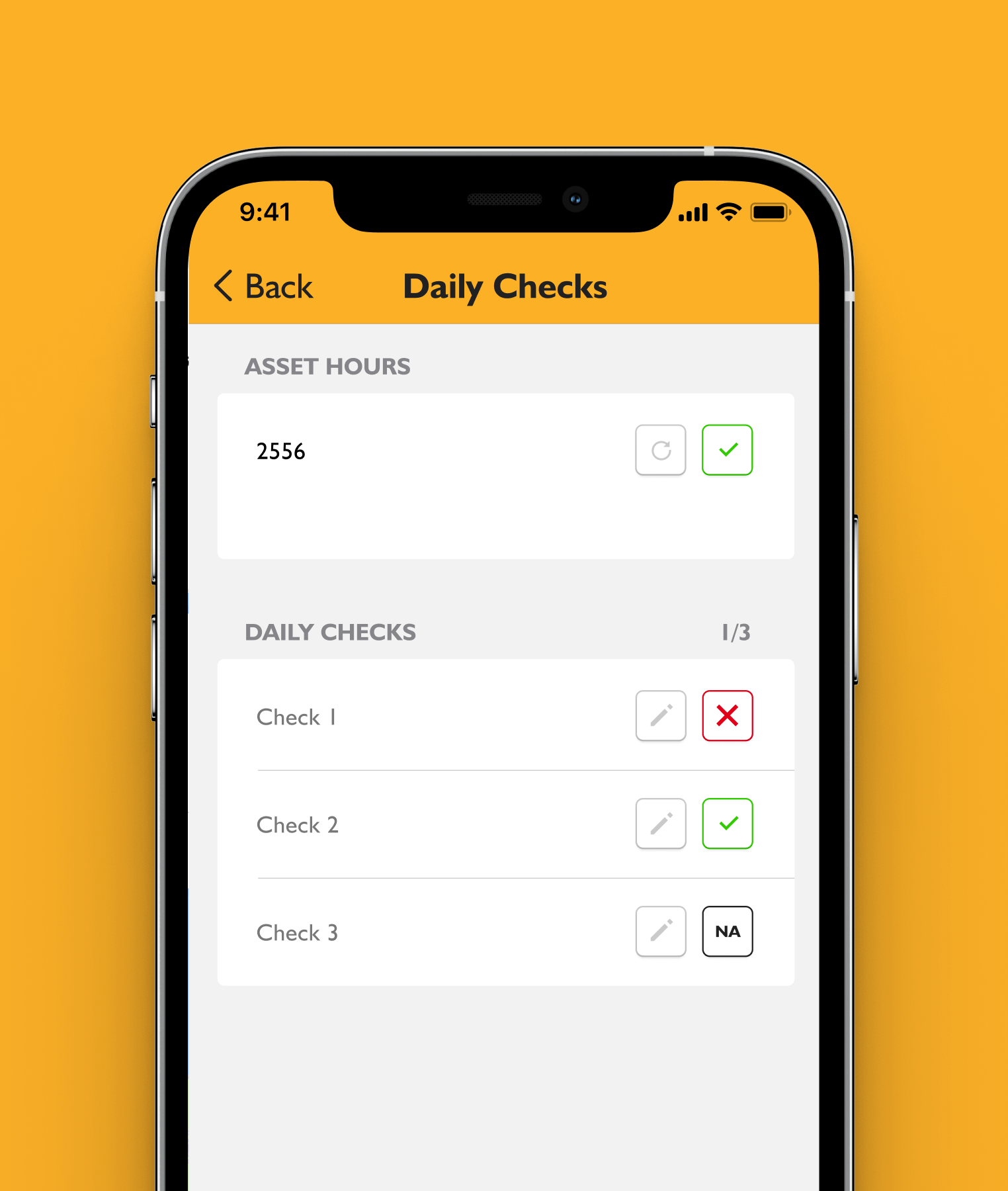

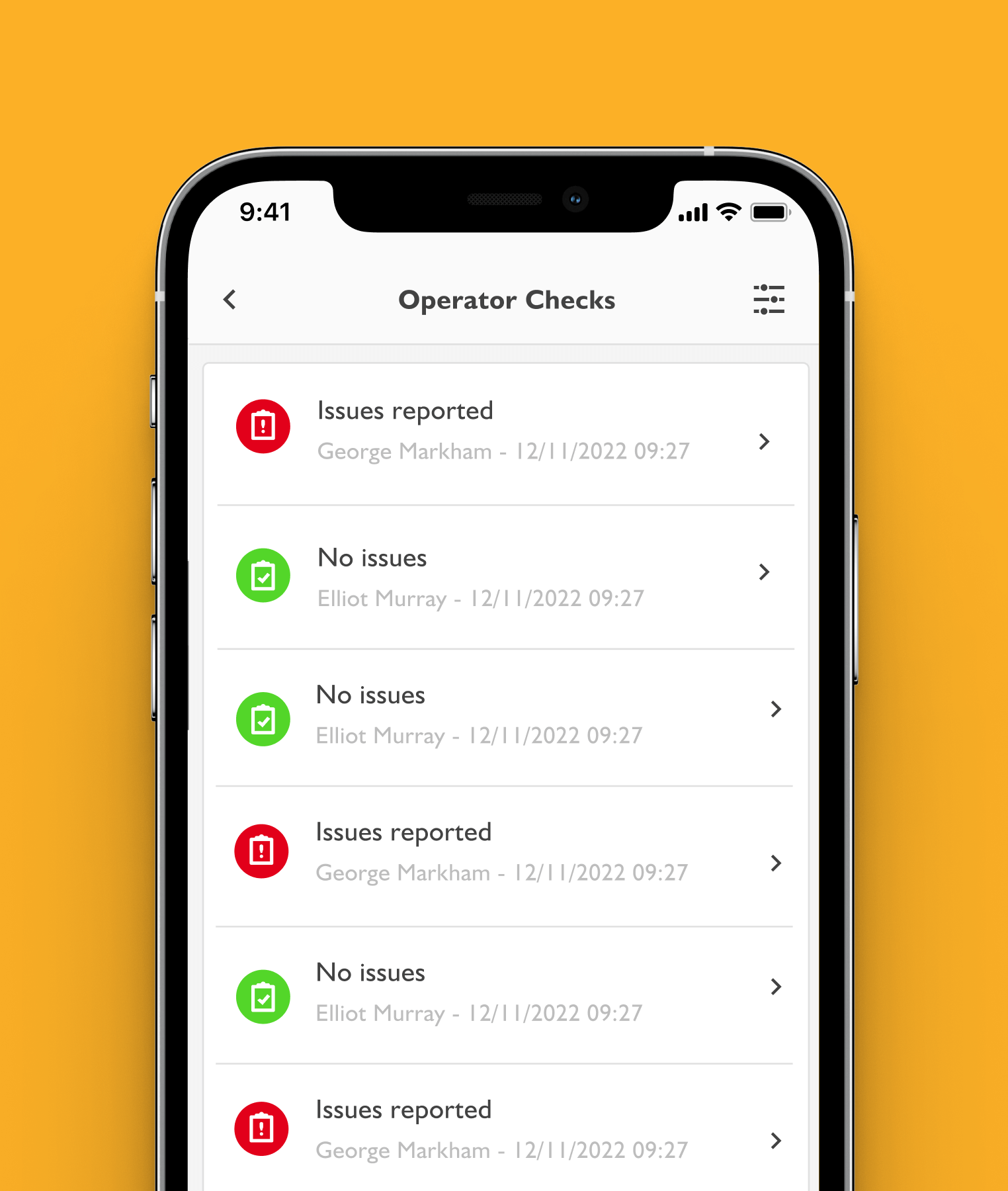

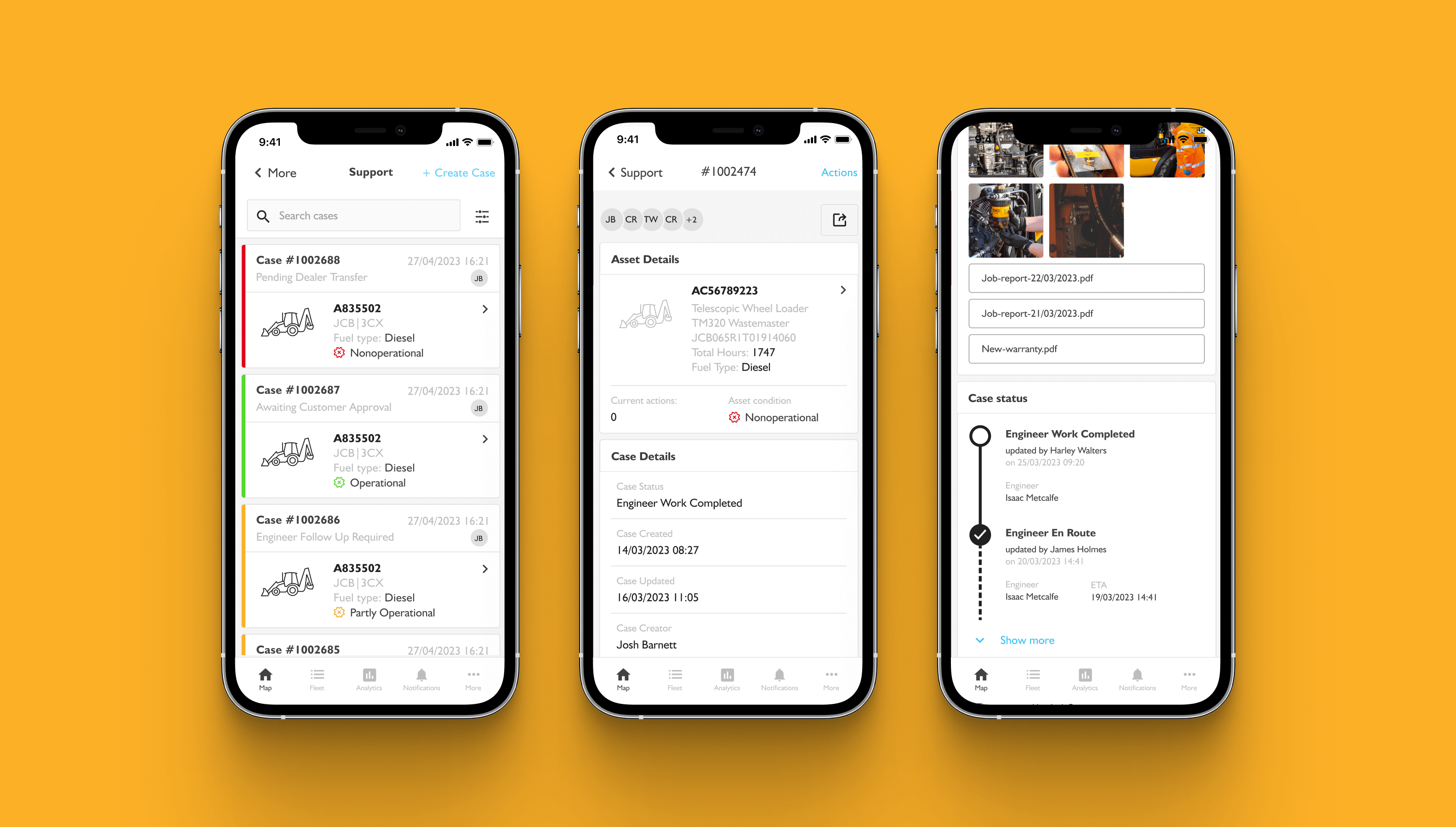

Rapid communication between machine operator and maintenance teams

Operators can report faults through the app. The maintenance team can then use reports developed by the system to identify a repair, communicating this back to the operator.

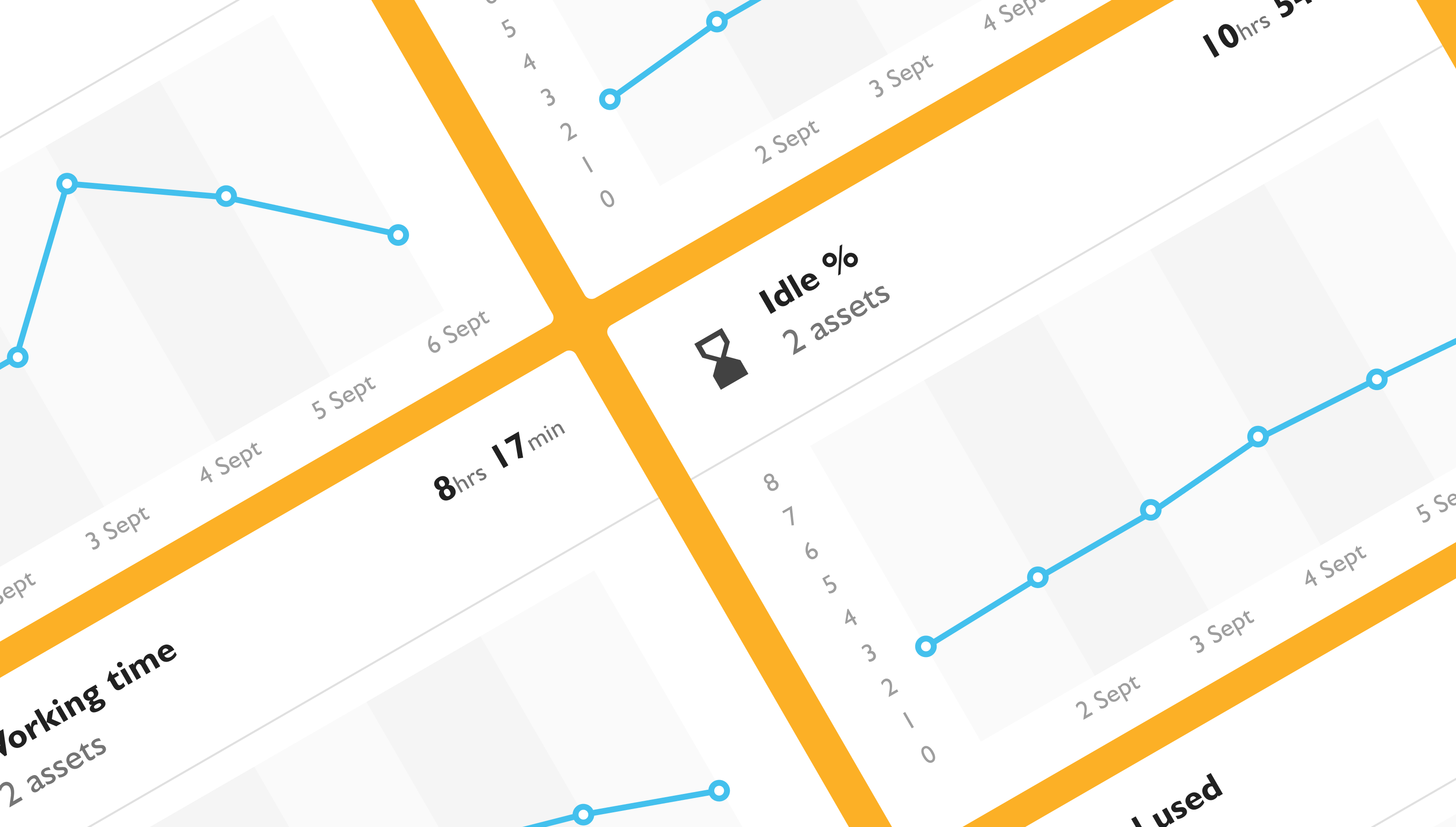

Fully customisable reports.

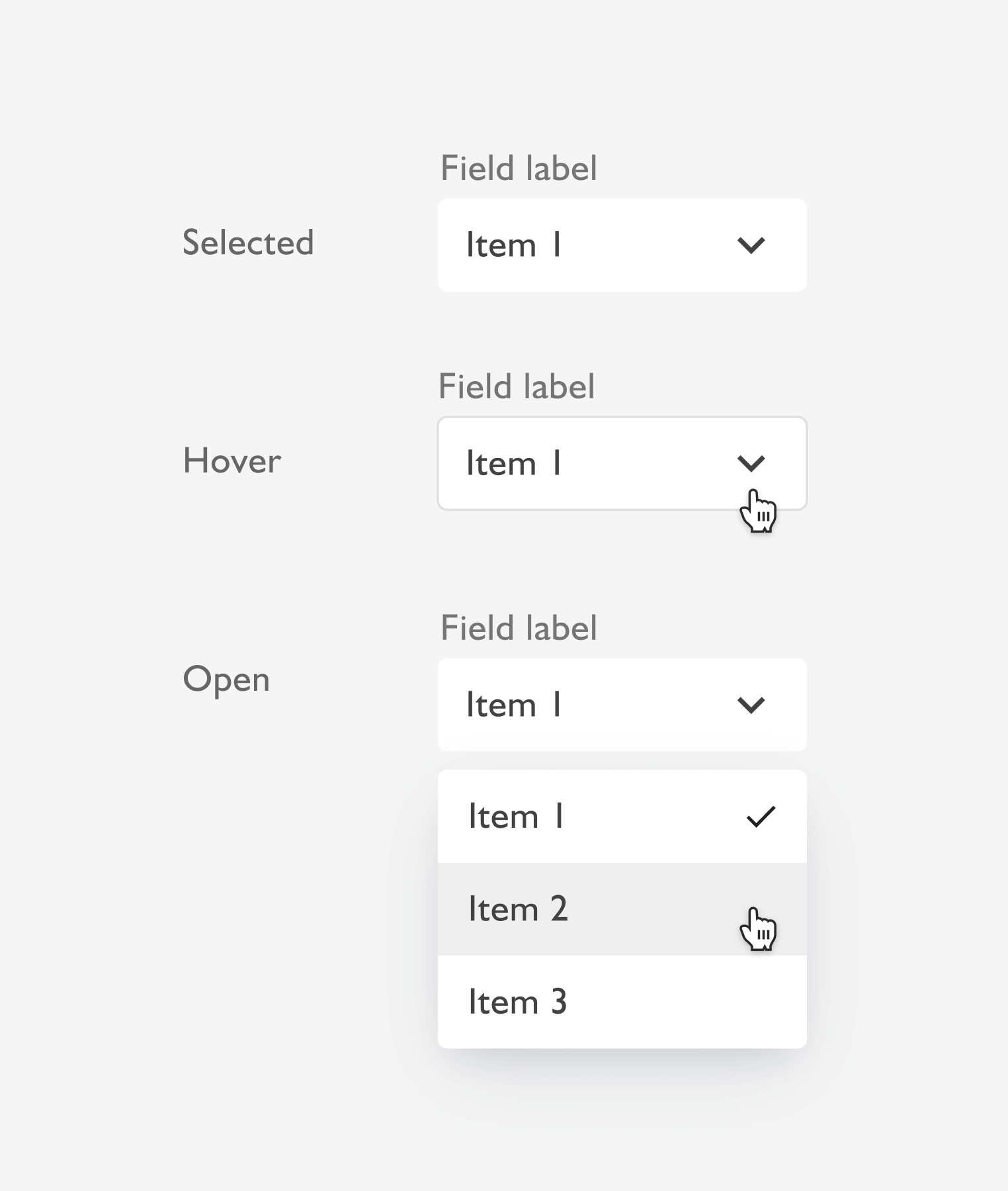

All reports are completely customisable by the user so they can choose which information is displayed and how, providing at-a-glance, one-click reporting on the information they require.

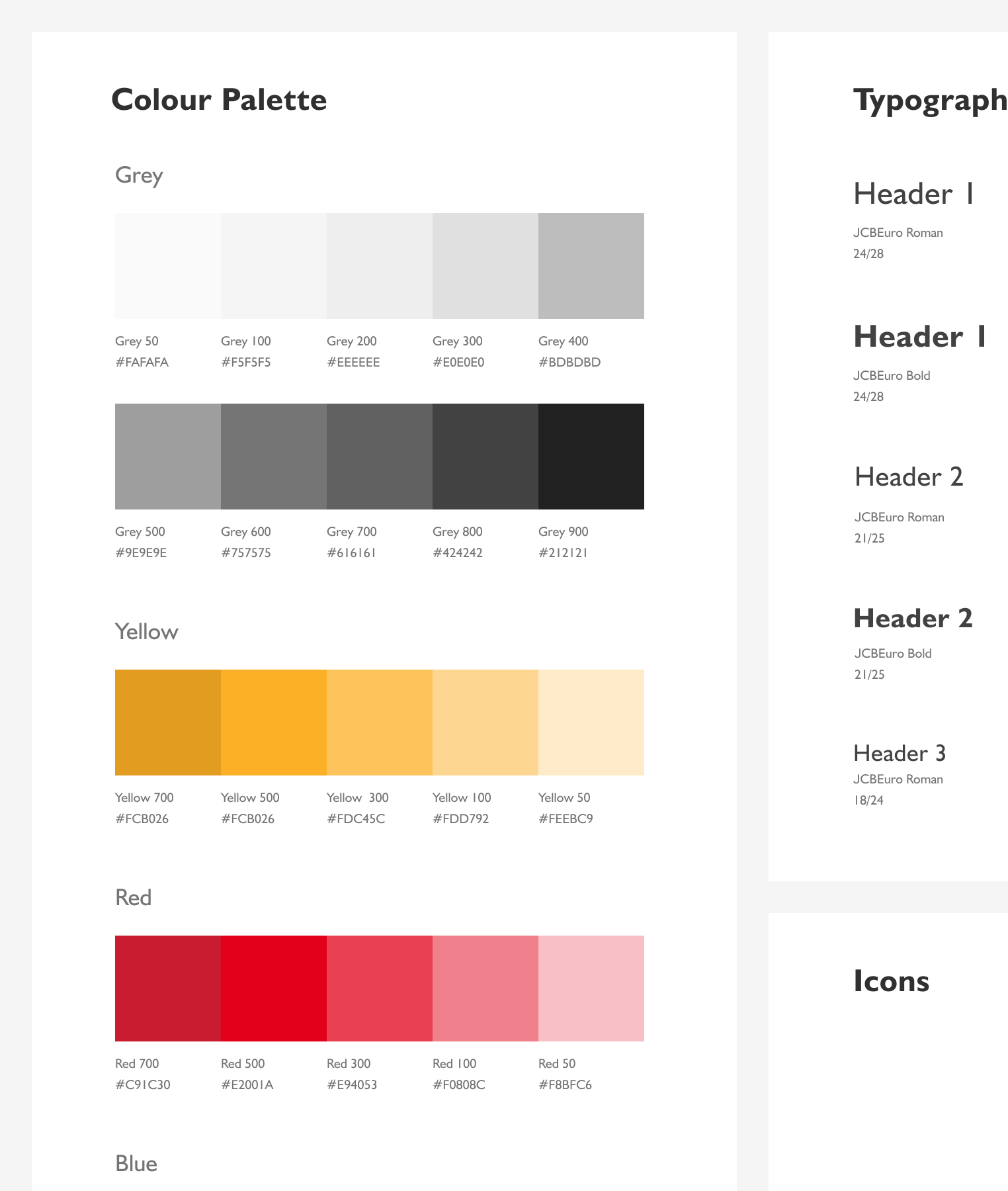

A more accessible application

The updated Livelink system made use of a more accessible user interface and language to ensure optimum user experience for all users from operators through to managers.

Contact

Let's talk

Say hello

hello@atomicmedia.co.uk

Careers

Join the team

Find the right career for you

View careers